Learn how edge computing solutions for operational technology can help the industrial, telecoms and energy sectors drive new opportunities for cost saving, efficiency with predictive maintenance, remote management, intelligent security and more.

Many would say that today’s frontier of digital innovation is in the cloud. But for organizations in the industrial, telecoms, utilities and energy sectors, the next wave of data-driven transformation is also happening at the physical ‘edge’ of their businesses – driving benefits of cost reduction, predictive maintenance, intelligent security and more. Industrial organizations can bring greater efficiency to operations with real-time production optimization, and apply smart remote management and automation to distributed facilities in challenging environments. For makers of operational technology serving industrial customers, this has great potential – but are you ready to take the edge opportunity?

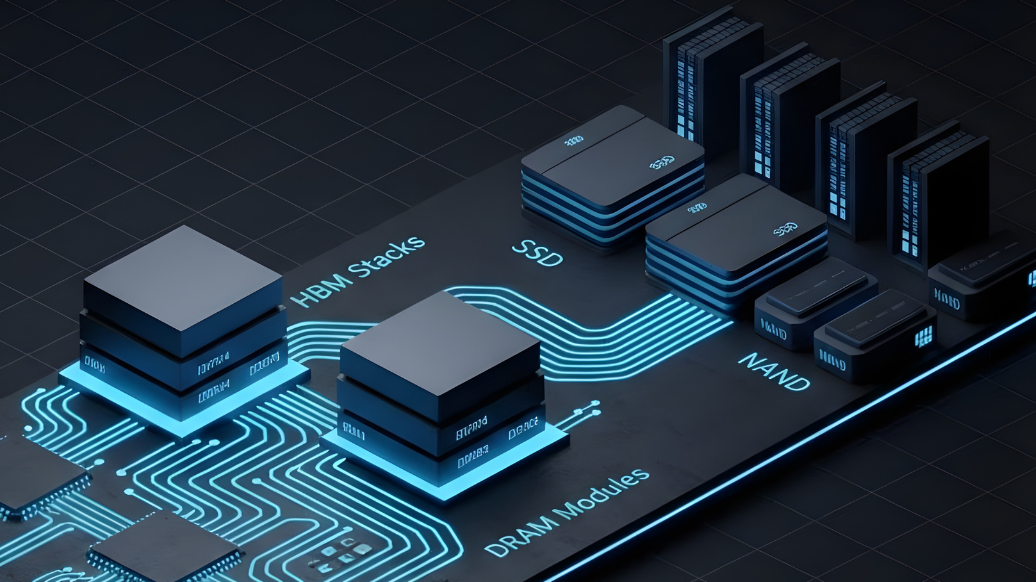

The ‘edge’ in this context is any place where day-to-day industry gets physically done – industrial plants, cellular tower sites, power stations, offshore platforms, or anywhere else out in the real world where these companies operate. These industries are processing business data in core data centers or cloud platforms – but the value of most data in their edge environments is largely unexploited. Huge volumes of data are now being created and captured at the edge by operational technology (OT) – industrial devices, equipment and machinery, fitted with sensors, video cameras and embedded systems.

Bringing network connectivity to OT at the industrial edge (sometimes described in terms such as ‘Industry 4.0’ or ‘Industrial IoT’) is unlocking more of this value. But moving edge data to a core data center or the cloud has many drawbacks and challenges around latency, connectivity, bandwidth costs and security. A new answer is to bring computing hardware and data analytics closer to the source of this data – directly into the industrial edge itself.

Data engines of industry

‘Edge computing’ solutions are transforming industrial OT for the new era of real-time data analytics. Makers of OT are realizing that they can extend the value of their products (even those that have previously contained no digital technology, such as an industrial pneumatic hose) by enabling them with edge data connectivity and computing capabilities – delivering a host of new insights and benefits for their customers, so they can:

- Improve production asset utilization and production efficiency.

- Use equipment sensor data to predict and minimize maintenance downtime.

- Manage and protect facilities remotely with automated edge systems.

- Monitor and control equipment’s environmental impact for compliance.

The edge computing solutions market will double in value to $21 billion by 2023, according to BCC Research. To help makers of industrial OT solutions claim their share of this edge opportunity, they are increasingly turning to Arrow as a trusted partner with the right capabilities, products and services – as well as the expertise and global resources to integrate and deliver these in a practical and collaborative way.

Edge opportunity in action

For example, a leading maker of industrial control systems has recently worked with Arrow to develop its next-generation edge solution for industrial equipment. The company has embedded sensors into their products to monitor the impact of environmental factors and improve asset utilization. The new solution makes it easier and more cost effective for organizations to remotely monitor assets – to reduce risk, maintenance cost and unplanned downtime, while improving safety and uncovering hidden opportunities to boost efficiency.

Arrow provides the custom circuit board to enable this edge solution. We also partnered with an ODM to produce a custom industrial-grade edge gateway that routes data for predictive maintenance to a cloud-based dashboard.

Ready to expand your edge perspective? Download our ebook on the evolving edge landscape and read our practical guide to developing your own edge OT solution. We’ve been helping product makers deliver on their technology vision for decades. Now we can help you power your industrial edge product strategy.