When we think about devices, our minds immediately conjure up the electronics around us. Phones, computers and other modern gadgets of the digital world have pervaded our society. However, the world around us is filled with everyday devices that are not considered “smart” and yet are of immense value to human productivity.

Wheels, levers, and lifting and turning devices are equally ubiquitous, greatly easing the physical demands of lifting, moving and turning everyday loads. Similarly, electromechanical devices like motors, generators and drills are crucial to human productivity and were cornerstones of the Industrial Revolution.

This mechanical/electromechanical world is poised for a significant transformation. This world exists mostly as an unconnected domain where machine operation is not interactive, noncommunicative and devoid of insights into the operation itself. The long and persistent reach of digital transformation is now enabling new innovations and making these devices interactive, connected and self-aware. As I spoke about in my last blog, this is really at the heart of the IT/OT convergence.

Embedded sensors, cameras and controls are now able to generate data about every aspect of device operation, and when transmitted to cloud applications, this data is affording new ways to reduce the total cost of ownership and improve performance. Examples include alerts for preventive maintenance, condition-based monitoring and failure prediction. In the home, locks, controls, lawn mowers, to name just a few, are getting smarter and can be accessed via mobile apps, giving consumers greater flexibility, predictability and control. More importantly, these devices can now interact with other systems through Application Programming Interfaces (APIs) that open a wide array of possibilities.

All this transformation creates fantastic opportunities not just for a smarter world but also for new business value, especially as we leverage new capabilities such as AI, XR (Virtual and Augmented Reality), and machine learning. Current industry players who do not embrace the impending change risk being left behind or disrupted by agile newcomers. Revamping product development processes to incorporate the value of connected products is crucial.

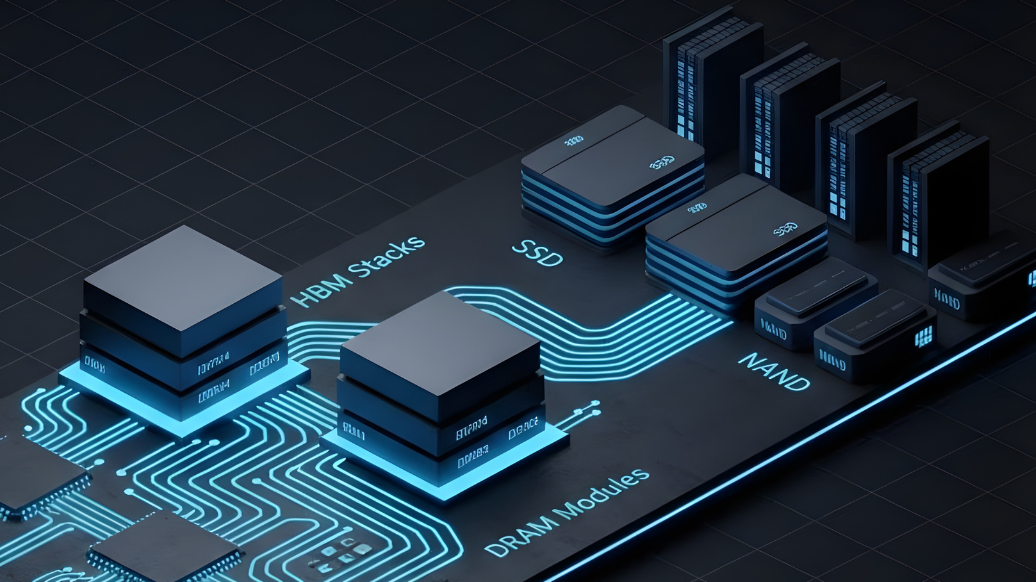

Connecting the unconnected requires the business to first contemplate the value gained from connectivity. As I have said before, just connecting something and calling it IoT, without a business case, is just a science project. There are three main areas of value typically experienced – cost reduction, customer satisfaction and/or increased revenues. In addition, stakeholders need to determine the most cost-effective technology path to unlock the value. Technology choices could include sensor elements, controls, signal aggregators, communication gateways, cloud infrastructure and analytics software. Finally, it’s essential to have an implementation model that makes appropriate trade-offs between in-house efforts and outside resources throughout the product life cycle.

Ensuring that the right technology partners and in-house skill sets are engaged to create the next-generation product lines is imperative. While this can be a challenge, ecosystem vendors and technology partners like Arrow are increasingly focused on offering a gamut of services to help implement new technology elements at scale. Companies can use some help on their IoT journeys, and Arrow is here to be a trusted partner.

We should all be super enthused about the improvements that await us. Human productivity enhancements and much more sophisticated mechanical infrastructure are not far off as the unconnected mechanical world embraces digital paradigms.